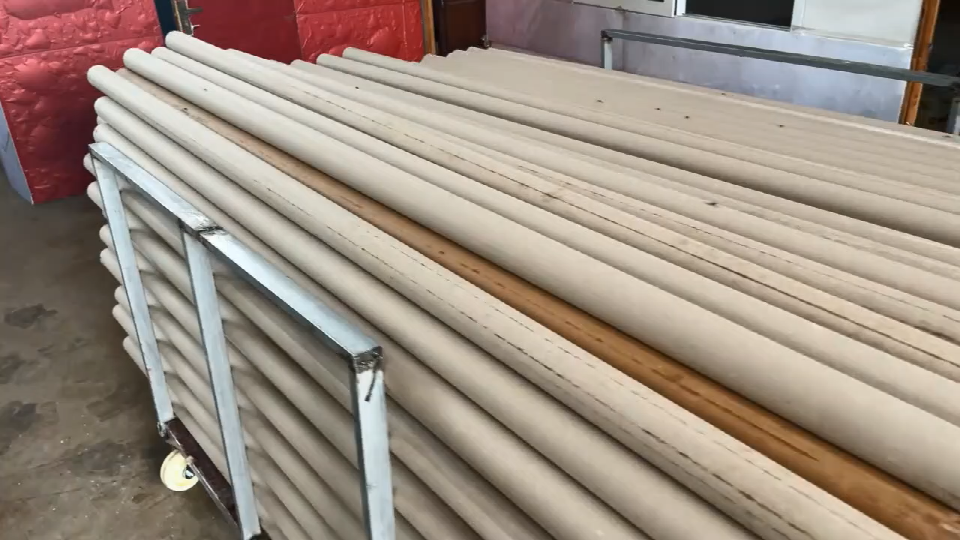

There is a big difference between parallel paper tube machine and spiral paper tube machine. The parallel paper tube machine uses the whole paper to form a tube in a direction parallel to the paper. The length of the paper tube depends on the width of the paper, and the thickness of the paper tube depends on the length of the paper. The spiral paper tube machine uses the strip paper that has been cut and rewound to adjust the angle according to the diameter of the required paper tube, and rolls the tube obliquely spirally. The thickness of the coiled tube of the spiral paper tube machine depends on the thickness of the paper and the number of layers. It is controllable and adjustable, and the length is generally unlimited. It can be precisely cut in the coiled tube according to your own need.Parallel paper tube machine appeared earlier, and later a large part of parallel paper tube machine was gradually replaced by the spiral paper tube machine. But parallel paper tube machine also has its own characteristics.

YDF16~76 Firecrackers Parallel Paper Tube Rolling Machine1. Directly make the roll paper into a parallel paper tube.

2. Adopt the way of rubber roller rolling, and the diaphragm pump computer controls the glue supply.

3. The equipment adopts Zhongda touch control system , and the servo motor frequency converter adopts the Ou Rui brand (National Warranty), which is durable.

4. All the actions of the whole machine are designed by numerical control, with a high degree of automation, which has the advantages of high operating stability, low failure rate in the production process, large output, and low noise;

YDF16~76 Firecrackers Parallel Paper Tube Rolling Machine

There is a big difference between parallel paper tube machine and spiral paper tube machine. The parallel paper tube machine uses the whole paper to form a tube in a direction parallel to the paper. The length of the paper tube depends on the width of the paper, and the thickness of the paper tube depends on the length of the paper. The spiral paper tube machine uses the strip paper that has been cut and rewound to adjust the angle according to the diameter of the required paper tube, and rolls the tube obliquely spirally. The thickness of the coiled tube of the spiral paper tube machine depends on the thickness of the paper and the number of layers. It is controllable and adjustable, and the length is generally unlimited. It can be precisely cut in the coiled tube according to your own need.Parallel paper tube machine appeared earlier, and later a large part of parallel paper tube machine was gradually replaced by the spiral paper tube machine. But parallel paper tube machine also has its own characteristics.

1. Scope of application

|

2. Technical features:

1. Directly make the roll paper into a flat roll paper tube.

2. Adopt the way of rubber roller rolling, and the diaphragm pump computer controls the glue supply.

3. The equipment adopts Zhongda touch control system , and the servo motor frequency converter adopts the Ou Rui brand (National Warranty), which is durable.

4. All the actions of the whole machine are designed by numerical control, with a high degree of automation, which has the advantages of high operating stability, low failure rate in the production process, large output, and low noise;

model | YDF- 1800 |

input power | AC380±10% 50Hz |

Pulley servo motor | 380V 3KW 2000R/Min |

Roller Servo Motor | 380V 3KW 2000R/Min |

paper feed motor | 1.5KW 4 poles |

Paper edge motor | 1.5KW 2 poles |

Dust removal fan motor | 1.5KW |

total power | 1 1KW |

input air pressure | >0.6MP |

gas flow | 2³ m /h |

Processing length | 1300mm |

Dimensions mm | 775 0 × 1635 × 1500 |

If you have any needs , please fill out the form below and we will contact you as soon as possible.