As a waste in sugar making plant, sugarcane bagasse is a good raw material for making tissue paper ,writing&printing paper and kraft paper.YDF bagasse paper manufacturers machine is a good choice.

This Machine is Parent Toilet Tissue Paper Roll Making Machine.There are waste paper recycling pulp machine and chemical virgin pulp making machine ,based upon the different original raw materials used for making toilet tissue paper.

Bagasse Paper Manufacturers Machine For Making Toilet Tissue Rolls

Bagasse paper manufacturers are big paper making factories,which could make paper from sugarcane bagasse.As a by-product in sugar making plant,sugarcane bagasse is usually as a waste in many countries,such as China,India,Vietnam etc.In fact,there is good fiber in sugarcane bagasse that could be used for making paper.YDF bagasse paper manufacturers machine could make toilet tissue paper or writing printing paper from sugarcane bagasse.Today we call this machine Toilet paper manufacturing machine,which could make a disposable household paper made from plant fibers (such as wood pulp, cotton pulp, straw pulp, etc.), which are cut and folded. Widely used in big scale tissue paper manufacturing plant.There are many types of toilet paper machine , which can be divided into roll toilet paper machine , coil paper machine, flat-cut toilet paper machine and removable toilet paper machine according to the packaging form. Among them, roll toilet paper machine is divided into two types: cored and coreless; according to color, it is divided into white toilet paper, colored toilet paper and virgin color toilet paper.

YIDAFA bagasse pulp toilet paper manufacturing machine belongs to chemical virgin wood pulp machine for making tissue toilet paper.The finished product will be white color parent jumbo tissue paper rolls.In tissue paper industry,wood pulp tissue paper is with best quality because of good fiber in wood pulp.Wood pulp machine for making tissue toilet paper needs to consume some chemical materials,such as caustic soda,bleaching materials etc.In this process,there will be waste water containing chemicals.How to process these chemical waste water is a big problem in modern society.Nobody in this world want to pollute the river.YIDAFA bagasse pulp toilet tissue paper manufacturing machine ,used in big scale paper mill plant ,is always including environmental protection equipment for processing waste water.Our company have professional technical team with rich experience.If the buyer's budget is rich,wood pulp toilet paper machine is the best choice in Africa,South America etc.

The English name is tissue paper (can be referred to as tissue) in Chinese pinyin (wèi shēng zhǐ), and the toilet paper placed in the bathroom is called toilet paper, which is mainly used for daily hygiene in people’s lives. One of the indispensable paper types in life. Its shape has a single square, which is called square tissue or facial tissue, and it is also rolled into a roller shape, which is called roll paper. They are usually made of cotton pulp, wood pulp, straw pulp, sugarcane bagasse pulp, mixed pulp, and waste paper pulp. Good quality toilet paper is made of virgin wood pulp. It is similar to the manufacturing process of ordinary paper, but it is required to be made into extremely thin Extremely fragile, the purpose of this is that it will rot when it encounters water, so as to achieve the purpose of environmental protection.

If the tissue paper is made from waste paper, the machine should be waste paper recycling machine to make toilet tissue paper.

If the tissue paper is made from wood pulp ,rice straw pulp,bamboo pulp,and sugarcane bagasse pulp, the machine should be chemical pulp machine for making toilet tissue paper.

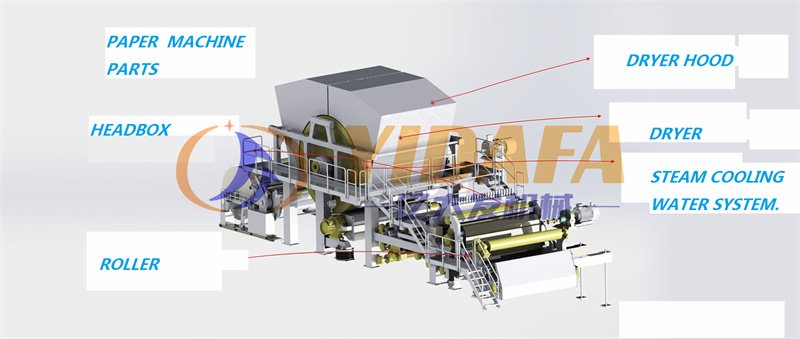

According to the working speed of the machine,toilet paper making machinery could be divided into (low speed)normal cyclinder toilet paper making machine and (high speed)crescent toilet paper making machine.

1.(Low speed) normal cyclinder toilet paper making machine

Cylinder machine (vat machine), a paper machine with a cylinder as a former. According to the different configurations of formers and drying cylinders, various types of paper machines can be formed, such as single cylinder wire single cylinder paper machine, double wire double cylinder paper machine, multi wire multi cylinder board machine, etc.

Generally, it is composed of one press, one roller press and 1 to 2 drying cylinders with larger diameters. Generally, cultural paper or wrapping paper is copied. The cylinder paper machine has a simple structure and low cost, and is mostly used by small and medium-sized paper mills. The new movable curved plate former (with pressure feeding) rotary paper machine can be adapted to produce corrugated base paper, liner board, toilet paper and medium and low-grade cultural paper. It can make 90-130g/m^2 different low-weight papers, and its speed can reach 220-250m/min, which can increase the output by nearly 2 times compared with the old-fashioned movable curved plate mesh slot paper machine.

2.(High speed)crescent toilet paper making machine.

If you have any needs , please fill out the form below and we will contact you as soon as possible.